OUR FACILITIES

State-of-the-Art

in the

Forging Industry

FORGING FACILITIES

Excellence in Forging Technology

Northstar Autocomp Pvt. Ltd. has equipped its forging facilities with advanced cutting-edge technologies and machineries, that deliver great efficiencies and effectiveness. With world class capacities and capabilities, we cater to diverse needs of our customers. All of our forging lines are highly flexible and automated, ensuring high quality, maximum productivity and employee safety.

Our forging Facilities consist of advanced Forging Presses and Upsetters

3000 Ton National Maxipres forging press (USA)

2500 Ton Ajax Forging Press (USA)

1600 Ton TMP Voronezh Forging press (Russia)

1300 Ton National Maxipres forging press (USA)

6’/1200 Ton Kaeserling Upsetter (Germany)

2’/400 Ton Stanko Upsetter (Russia)

600Ton Spiertz Coining Press (Germany)

320mm Reduce Roller (Italy)

400mm Reduce Roller (Italy)

300mm Reduce Roller (USA)

750KW, 650KW, 500KW, 450KW, 400KW Billet Heater (Inductotherm and Electrotherm)

750KW and 300 KW End-bar Heater (Electrotherm)

HEAT TREATMENT

Enhanced Durability Processing

Our state-of-the-art heat treatment facility is equipped with the latest technology and advanced equipment, ensuring precise and efficient heat treatment processes for our products. Our 2 Ton/Hour gas-fired continuous Hardening and Tempering Furnace features an instrumentation panel for real-time temperature display and recording across 16 different zones.

An advanced, fully automated gas-fired heat treatment facility is at the heart of our operations. Our hardening and Tempering Furnace boasts separate polymer and oil quenching tanks, along with a dedicated washing unit to eliminate impurities and excess oil post-quenching.

Furthermore, our Press lines come equipped with Control Cooling Furnaces tailored for micro-alloys, ensuring precise micro-structures and upholding the highest quality standards.

Additionally, our furnace is SCADA controlled, offering data logging and history recording capabilities. Furthermore, our IsoThermal Annealing Chamber ensures consistent heating and cooling for achieving the desired material properties.

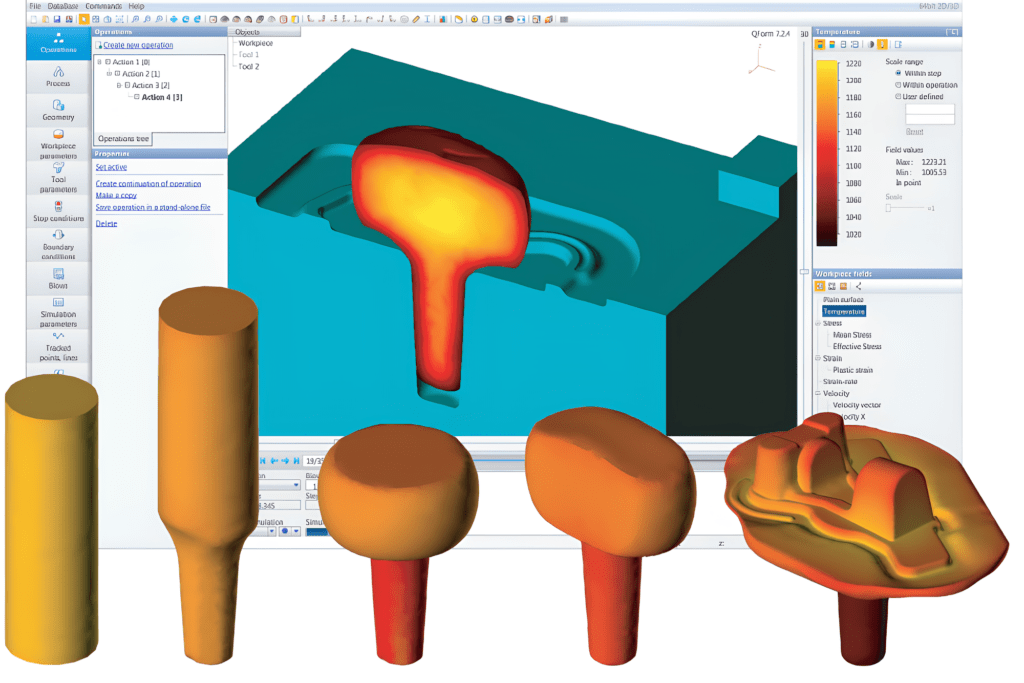

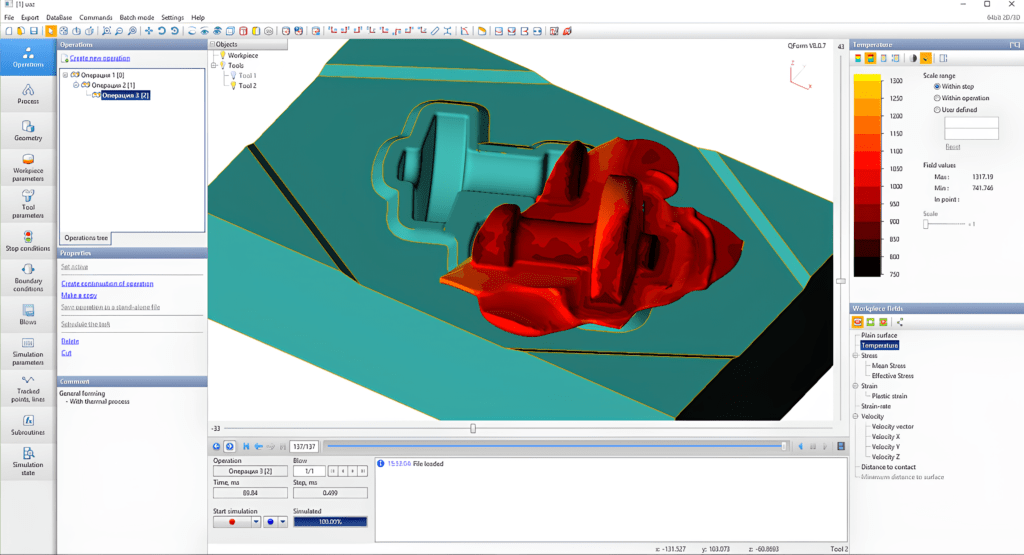

DIE DESIGN & MANUFACTURING

Innovative Die Design and

Precision Manufacturing Solutions

Our cutting-edge Design Lab is equipped with the latest technological tools and software, enabling seamless integration of design, prototyping, testing, and manufacturing processes. Our highly experienced and skilled engineering team excels at creating and reverse engineering even the most critical components, consistently delivering top-notch solutions to our clients

MACHINERY

Modern, Reliable Machinery

for Superior Output

Our advanced Machining Lines ensure minimal lead times and exceptional precision. Each component is custom-tailored to meet specific customer requirements, adhering to tight tolerances. Supported by cutting-edge CNC machines from Doosan (Korea) and a skilled engineering team, we deliver maximum output with zero rejection rates, especially for Critical Safety Parts. Our comprehensive machining division works closely with a dedicated quality control department, ensuring that all final products meet the highest standards. Additionally, our dual-spindle surface induction machines, equipped with PLC-controlled stress-relieving furnaces, guarantee precise case depth hardness and control.

MACHINE SHOP

Efficient and precise Machining

We have a unique set of machining lines that prioritize short lead times and exceptional precision. Our focus is on manufacturing components tailored to the specific needs of our customers while maintaining extremely tight tolerances. With our advanced machining division and skilled engineering team, we ensure zero defects and maximize the production of critical safety parts. Our comprehensive machining division is complemented by a quality control department that ensures the final parts meet the high-quality standards set by our customers .

QUALITY & INSPECTION

Thorough Inspection,

Unmatched Quality

We utilize state-of-the-art technology to maintain the highest quality standards throughout our manufacturing process. Our inspection includes precise measurements for accurate dimensions, ultrasonic testing for Axle Shafts, and laser marking for clear identification. We assess hardness with Rockwell, Brinell, and Vickers testers and perform Magnetic Particle Inspection (MPI) for thorough quality evaluation.