Die Design & Manufacturing

Die Design & Manufacturing

Our Design Lab is furnished with cutting-edge tools and software that enable us to handle design, prototyping, testing, and manufacturing processes. Our highly experienced and skilled engineering team excels in creating and reverse engineering even the most crucial components, delivering exceptional results to our clients.

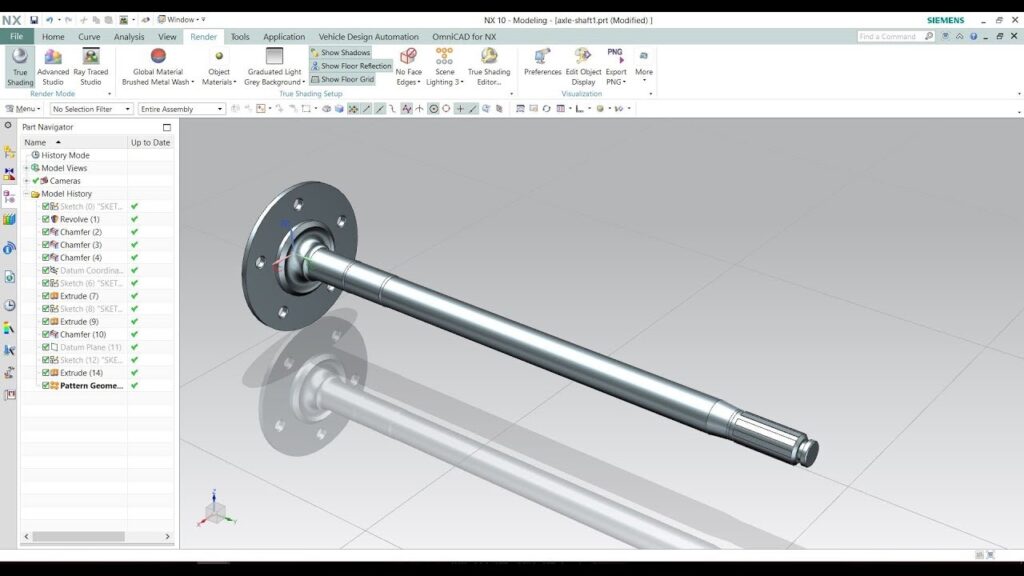

To support our design and manufacturing operations, We utilize advanced CAD/CAM programs such as Solidworks, WorkNc, and Vera Cad. These programs allow us to construct critical parts with precision and ensure the repeatability of dies, even after they have exceeded their specified lifespan.

For optimization and efficiency, we employ QForm 3D simulation software. By simulating and optimizing the forging parts offline, we minimize ineffeciencies and proactively detect any potential production failures, ensuring smoother manufacturing processes.

The design & engineering facility comprises of:

Northstar Autocomp Pvt Ltd. emphasizes Value Analysis and Value Engineering (VAVE) to offer innovative proposals while maintaining the quality and durability of its products.

To accelerate response time in developing new parts, having a state-of-the-art CAD/CAM/CAE (Computer-Aided Design/Computer-Aided Manufacturing/Computer-Aided Engineering) infrastructure

QForm can play a crucial role in predicting and preventing potential production issues, minimizing inefficiencies, and enhancing the overall manufacturing process.

Die Designing & Manufacturing Facilities

Image

Image

Image 2

Image

Image 3

Image